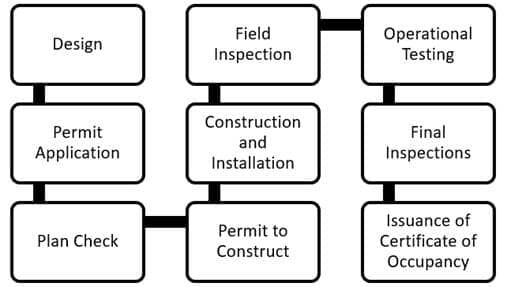

Acceptance testing is performed during the Operational Testing phase of project permitting (shown in Figure 14.1-1) and prior to final inspections and the issuance of the Certificate of Occupancy. See Nonresidential and Multifamily Compliance Manual Chapter 2 for more information regarding the phase of project permitting.

Figure 14.1-1: Idealized International Code Council Permitting Process for Building Permit Applications

Source: California Energy Commission staff

However, it is advisable (although not required) to include professionals who are knowledgeable regarding the acceptance test procedures and requirements in the Design phase as well.

From simple thermostats and manual light switches to complex building automation systems, controls are integral to building health, safety, comfort, and energy efficiency.

Acceptance test requirements specify targeted inspections and functional performance tests that demonstrate that the building components, equipment, systems, and interfaces conform to the 2022 Building Energy Efficiency Standards (or Energy Code, inclusive of Reference Nonresidential Appendix NA7), as specified on applicable construction documents.

This helps ensure that the building achieves the energy savings potential specified in its design and protects installing technicians by providing demonstrable proof that the system functioned as required by code when it was installed.

Please see Nonresidential and Multifamily Compliance Manual Chapter 2 for a complete discussion concerning the roles and responsibilities of all parties

The field technician is responsible for performing and documenting the results of the acceptance testing procedures on the certificate of acceptance documents. The field technician must sign the certificate of acceptance to certify that the information provided on the certificate of acceptance is true and correct. The field technician does not require a contractor’s, architect's or engineer's license but may require certification as an acceptance test technician (ATT).

While it is preferred that the same field technician that performed the installation also perform the acceptance test, it is not required. A separate technician (or contractor, engineer, architect, or even the responsible person) can perform the acceptance test and sign for the field technician.

An ATT is a certification standard for technicians, contractors, engineers, architects, and commission agents that design, install, and commission (perform acceptance testing) for lighting controls and mechanical system in newly constructed or existing nonresidential buildings or spaces.

The certification is restricted to applicants with a minimum of three years of professional experience and expertise in either lighting or mechanical controls. Qualifying experience for certification is provided by verifiable employment as an electrical contractor, certified general electrician, licensed architect, professional engineer, controls installation and startup contractor, HVAC installer, mechanical contractor, Testing and Balancing certified technician, or certified commissioning professional with verifiable experience in lighting controls or HVAC installations. ATTs are provided classroom and laboratory training to perform acceptance testing. ATTs must pass classroom and laboratory testing to gain their certification. The ATT is required to work with the California Energy Commission (CEC) approved acceptance test technician certification provider (ATTCP) to track and verify quality assurance of their acceptance test performance.

- Mechanical ATTs may perform the HERS field verification and diagnostic tests covered in the scope of Nonresidential Appendix NA2. These HERS tests are commonly performed by HERS Raters but can be performed by mechanical ATTs with the approval of the local jurisdiction.

- Other acceptance tests, such as those for covering processes and building envelope do not require a certified ATT.

More information on becoming certified and other information on ATTs can be found at http://www.energy.ca.gov/title24/attcp/.

A certificate of acceptance must be signed by a responsible person who is licensed and eligible under Division 3 of the Business and Professions Code to take responsibility for the scope of work documented by the certificate of acceptance. In assuming responsibility for the work as a whole, the responsible person assumes responsibility for the acceptance testing work performed by his or her field technician, agent or employee.

The responsible person may perform the acceptance testing if qualified to do so. If qualified, the responsible person must complete and sign both the field technician's signature block and the responsible person's signature block on the Certificate of Acceptance document. (In addition to being licensed, a responsible person that conducts his or her own testing must also be a certified ATT if he or she is performing an acceptance test that requires a certified ATT.)

Nonresidential Duct Leakage Testing. When single-zone, constant volume space-conditioning systems (1) serving less than 5,000 ft² of floor area and (2) having more than 25 percent of the system surface duct area are located in unconditioned space, duct sealing is prescriptively required by §140.4(l) for newly constructed buildings and §141.0(b)2C, D, and E for HVAC alterations. A HERS Verification of the duct system must be conducted by a certified HERS Rater to verify that the air distribution duct leakage of the system is within specifications required by the Energy Code. The HERS Verification is performed each duct system or on a sample (one in seven) of duct systems. For example, a series of buildings on a project site where the contractor is installing new HVAC systems (qualifying as indicated above) would require that the associated ducts be tested for leakage (limited to 15 percent of the system air volume). The installing contractor can perform and document the duct leakage test (NRCA-MCH-04a-A) and place seven of the completed NRCAs in a group. The group is then given to a HERS Rater, who selects one at random and performs the same acceptance test. The HERS Rater then records only the HERS Verification that they performed in the HERS data registry.

As an alternative for the contractor or builder (and approved by the enforcement agency), an ATT may perform and document the duct leakage test (NRCA-MCH-04b-A) and avoid using a HERS Rater. The ATT must record the duct test in the ATTCP database tracking system. In either case, each duct system must be tested. Multifamily Indoor Air Quality Testing. New for the 2022 Energy Code, mechanical ATTs may also perform the indoor air quality (IAQ) HERS Verifications specified in Reference Appendix NA1 (see Table 14.1-1) in place of HERS Raters for low-rise multifamily buildings.

| HERS Verification | Verification Description | ATT-NRCA Form and Energy Code Reference |

|

Dwelling-Unit Mechanical Ventilation Airflow – Continuous Operation |

Verify that whole-building ventilation system complies with the airflow rate required by ASHRAE Standard 62.2. |

NRCA-MCH-20a-A, and NRCA-MCH-20c-A |

|

Dwelling-Unit Mechanical Ventilation Airflow – Intermittent Operation |

Verify that whole-building ventilation system complies with the airflow rate required by ASHRAE Standard 62.2. |

Forms and procedures posted with CEC Manufacturer Certification Program (https://www.energy.ca.gov/rules-and-regulations/building-energy-efficiency/manufacturer-certification-building-equipment-6) Energy Code Reference: NA2.2.4.2 |

|

Kitchen Local Mechanical Exhaust Verification |

Verify using certified performance rating data from the HVI Directory or the AHAM Directory for determining that the kitchen exhaust system complies with listed requirements. |

NRCA-MCH-20a-A, and NRCA-MCH-20b-A |

|

Heat Recovery Ventilation (HRV) or Energy Recovery Ventilation (ERV) Rated Performance Verification |

Verify that HRV or ERV system meets or exceeds the performance required for compliance. |

NRCA-MCH-20a-A, and NRCA-MCH-20d-A |

|

Building Envelope Air Leakage |

The purpose of this test procedure is to measure the air leakage rate through a multifamily dwelling unit enclosure measured in cubic feet per minute |

NRCA-MCH-21-A |

Source: California Energy Commission

A commissioning provider (also referred as a commissioning agent) is not defined by the Energy Code but is an industry term for a person who may be contracted by the owner to verify functional performance testing is conducted (among other responsibilities) to ensure proper performance at building turnover. Commissioning during construction is required by §120.8. In general, newly constructed nonresidential buildings with more than 10,000 square feet of conditioned floor area must comply with all of the requirements in §120.8 (full commissioning). Smaller buildings are required to complete just the design review phase of commissioning. The commissioning requirements in §120.8 do not apply to healthcare facilities, which have parallel requirements in Chapter 7 of the California Administrative Code (Title 24, Part 1), and do not apply to additions or alterations to existing buildings.

Although system commissioning and acceptance testing are related, not all projects that require acceptance testing will also require full commissioning. If a commissioning agent is part of the project team, they will often be present for functional performance testing of major building systems to verify the tests were completed and passed on behalf of the building owner. (Commissioning agents may instead perform acceptance testing themselves, and if this is the case, they may also need to be a certified ATT). See Nonresidential and Multifamily Compliance Manual Chapter 2 for more information regarding commissioning and commissioning agents.

The certificate of acceptance must be submitted to the enforcement agency, typically at final inspection, to receive the certificate of occupancy. Many enforcement agencies will issue a provisional certificate of occupancy and allow the builder to fix or complete specific elements within a specified time frame. Enforcement agencies may not release a final certificate of occupancy unless the submitted certificate of acceptance demonstrates that the specified systems and equipment have been shown to perform in accordance with the applicable acceptance requirements.

The enforcement agency has the authority to require the field technician or responsible person to demonstrate competence to its satisfaction. When a certified ATT is required to complete an acceptance test, the enforcement agency may verify the ATT certification status through the ATTCP before issuing a certificate of occupancy. For details on how to do this most efficiently, see the Section 14.1.3 below. Please see Nonresidential and Multifamily Compliance Manual Chapter 2 for more information regarding enforcement agencies roles and responsibilities.

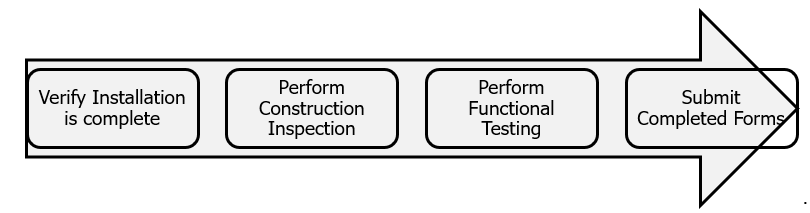

See Nonresidential Multifamily Compliance Manual, Chapter 2 for a more complete discussion of the permitting process. As was shown in Figure 14.1-1, the acceptance testing is performed during the Operational Testing phase of permitted construction. The acceptance process itself follows four major steps as shown in Figure 14.1-2.

Figure 14.1-2: Steps in the Acceptance Testing Process

Source: California Energy Commission

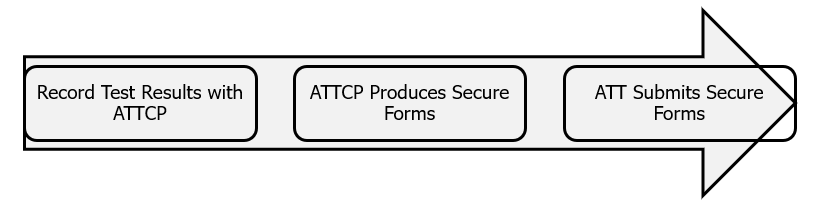

The acceptance test process is slightly different when an ATT is required. As shown in Figure 14.1-3 the difference is in the use of the ATTCP when completing and submitting the completed forms (the final step in the general acceptance test process shown in Figure 14.1-2).

Figure 14.1-3: Final Step to Submit Completed Forms for the ATT Acceptance Testing Process

Source: California Energy Commission

Reviewing the acceptance requirements with the contractor before installation may help the process run smoothly. In some cases, performing tests immediately after installation is most economical, though this requires the complete installation of any associated systems and equipment necessary for proper system operation. Awareness of the acceptance test requirements can allow the contractor to identify a design or construction practice that would not comply with the Energy Code before equipment installation.

A technician or ATT assumes the responsibility for performing the required acceptance test requirement procedures in NA7 and reproduced on the Certificates of Acceptance for convenience. The CEC expects that the same technician or ATT that installed the efficiency feature will perform all the required acceptance tests for that feature, but this is not required. The technician or ATT who performs the acceptance test is responsible for identifying and remediating all performance deficiencies, repeating the test (if necessary) until the specified efficiency feature is performing in accordance with the acceptance test requirements.

Additionally, the CEC makes the following recommendations as a good industry practice, but are not required:

- When planning construction, consider costs of testing within subcontractor bids, scheduling time within the overall construction schedule and coordination with commissioning if required on the project.

- Purchasing sensors and equipment with calibration certificates often reduces the amount of time required for site calibration, which can lower overall costs.

- In some cases, performing tests immediately after installation or during set-up and commissioning is most economical, though this requires the complete installation of any associated systems and equipment necessary for proper system operation.

The technician or ATT is responsible to verify that the efficiency feature is installed as indicated by the approved plans including the certificate of compliance. These plans, including the certificates of compliance, are approved by the enforcement agency during the permit application phase (see Figure 14.1-1). See Nonresidential and Multifamily Compliance Manual, Chapter 2 for a detailed explanation of the permitting process and roles and responsibilities. The certificates of compliance are completed by using the Virtual Compliance Assistant (VCA) Tool. The VCA Tool will indicate what acceptance tests are to be completed for each efficiency features at permit application phase. The technician or ATT must verify with the help of the responsible person what acceptances are to be performed and on what efficiency features. The technician or ATT is then to install the efficiency feature and ensure that it is operational and ready for acceptance testing.

The construction inspection for acceptance testing is primarily a visual inspection of the installed efficiency feature (including records inspection), but may include some measurements. The construction inspection helps to ensure that the efficiency feature is present and capable of complying with the acceptance test requirements for the functional test.

The field technician or ATT performs the required construction inspection before functional testing as prescribed by the requirements in NA7 for each acceptance test.

The technician or ATT performs the functional testing requirements for each acceptance test as prescribed in NA7. The functional tests generally focus on the controls for the efficiency feature indicating a pass/fail for each setting. However, several functional tests do require specific measurements and calculations to pass, such the outdoor air volume delivered to a space.

Once the efficiency feature passes the acceptance test requirements, the technician or ATT who performed the acceptance test completes the respective Certificate of Acceptance form and signs it to assert that the information recorded on the certificate is true and correct. In some instances, it may be beneficial for the technician or ATT to complete the Certificate of Acceptance form when the efficiency feature does not pass acceptance testing. This may help the technician or ATT identify the issues or errors that the efficiency feature is having that prevent it from passing. This information can be used to convey these issues to the responsible person for the project for remedy. A responsible person for the project must also sign the form to ensure that the performance of the scope of work specified by the Certificate of Acceptance and the test results provided by the field technician are complete.

As noted previously, the responsible person may also perform the field technician's responsibilities and, if so, must sign the field technician declaration on the certificate of acceptance. If the acceptance test requires a certified ATT, the responsible person must be a certified ATT to perform the acceptance test.

If the project includes duct leakage testing and a HERS Rater verification is to be performed, then the Certificate of Verification compliance documentation must be registered with the HERS Provider. See Nonresidential and Multifamily Compliance Manual, Chapter 2 for a more detailed discussion of HERS Verification process.

The completed and signed Certificate of Acceptance form must be submitted to the enforcement agency in accordance with the local laws, ordinances, regulations, or customs.

Building inspectors may review the forms during inspection. Inspectors can also verify that the ATT certification status through the ATTCP online certification lists. Finally, the inspector can verify that the completed form is valid by relying on the watermark provided by the ATTCP or by contacting the ATTCP to verify the form over the phone or via internet. Some ATTCPs provide a QR-Code for a quick and simple verification. ATTCP documents should not be accepted if completed by hand, completed electronically outside the ATTCP online interface, or fails to show the ATTCP logo and watermark.

Certificate of acceptance (NRCA and LMCA) forms consist of worksheets to document the results of construction inspections and functional testing, as well as a signatory page. Table 14-1 shows the NRCA and LMCA documents and related references.

Naming Convention. The name of the compliance document can give you clues about the documents use. The NRCA prefix indicates a nonresidential certificate of acceptance which is used for nonresidential buildings and multifamily buildings with four or more habitable stories. The LMCA prefix indicates a low-rise multifamily certificate of acceptance which is used for multifamily buildings with up to three habitable stories. The next set of letters specifies the building component; for example, “LTI” indicates indoor lighting. The suffix will tell you whether a certified acceptance test technician “-A” or field technician “-F” is appropriate to perform the functional performance test. Remember that an ATT can act as a field technician, but a current ATT certification is required for someone to sign as an ATT.

Component | Certificate of Acceptance Form Name | Energy Code Reference | Reference Nonresidential Appendix NA7 | Required Certification |

Envelope | NRCA-ENV-02-F LMCA-ENV-02-F Fenestration | NONE | ||

Envelope | NRCA-ENV-02-F LMCA-ENV-02-F Window Films | Made available to ATT | ||

Envelope | NRCA-ENV-02-F LMCA-ENV-02-F Dynamic Glazing | Made available to ATT | ||

Envelope | NRCA-ENV-03-F LMCA-ENV-03-F Clerestories for PAF | §140.3(d)1 §170.2(e)2xii | Made available to ATT | |

Envelope | NRCA-ENV-03-F LMCA-ENV-03-F Interior and Exterior Horizontal Slats for PAF | §140.3(d)2 §170.2(e)2xii | Made available to ATT | |

Envelope | NRCA-ENV-03-F LMCA-ENV-03-F Interior and Exterior Lighting Shelves for PAF | §140.3(d)3 §170.2(e)2xii | Made available to ATT | |

Mechanical | NRCA-MCH-02-A Outdoor Air | ATT | ||

Mechanical | NRCA-MCH-03-A Constant Volume, Single Zone, Unitary Air Conditioner and Heat Pump Systems | §120.1(c)2 §120.2 §120.5(a)2 160.3(d)1B | ATT | |

Mechanical | NRCA-MCH-04a-H LMCA-MCH-04a-H Duct Leakage | NONE | ||

Mechanical | NRCA-MCH-04b-A LMCA-MCH-04b-A Duct Leakage | §120.5(a)3, §120.4(g) §141.0(b)2Dii §160.3(d)1C | ATT | |

Mechanical | NRCA-MCH-05-A Economizer | ATT | ||

Mechanical | NRCA-MCH-06-A Demand Control | ATT | ||

Mechanical | NRCA-MCH-07-A Supply Control | ATT | ||

Mechanical | NRCA-MCH-08-A Valve Leakage | §120.5(a)8 §140.4(k)1 §140.4(k)5 §140.4(k)6 | ATT | |

Mechanical | NRCA-MCH-09-A Supply Water | ATT | ||

Mechanical | NRCA-MCH-10-A Hydronic System | ATT | ||

Mechanical | NRCA-MCH-11-A Demand Shed Control | ATT | ||

Mechanical | NRCA-MCH-12-A FDD Packaged Direct | ATT | ||

Mechanical | NRCA-MCH-13-A (FDD AHU/ZTU | ATT | ||

Mechanical | NRCA-MCH-14-A Energy Storage | ATT | ||

Mechanical | NRCA-MCH-15-A Thermal Energy Storage | ATT | ||

Mechanical | NRCA-MCH-16-A Supply Air Temperature | ATT | ||

Mechanical | NRCA-MCH-17-A Condenser Water Temp | This test is required if this control strategy is implemented. §120.5(a)16 | ATT | |

Mechanical | NRCA-MCH-18-A EMCS | §110.2(e) §120.2(h) §120.5(a)17 §130.4(b) §130.5(f) §150.0(k) | ATT | |

Mechanical | NRCA-MCH-19-A Occupancy Sensor | ATT | ||

Mechanical | NRCA-MCH-20a-H LMCA-MCH-20a-H Multifamily Dwelling Inspection | §160.2(b)2Av §160.2(b)2Aix | ATT or HERS Rater | |

Mechanical | NRCA-MCH-20b-H LMCA-MCH-20b-H Multifamily Kitchen Exhaust | ATT or HERS Rater | ||

Mechanical | NRCA-MCH-20c-H LMCA-MCH-20c-H Multifamily IAQ System | ATT or HERS Rater | ||

Mechanical | NRCA-MCH-20d-H LMCA-MCH-20d-H Multifamily Dwelling HRV/ERV System | ATT or HERS Rater | ||

Mechanical | NRCA-MCH-21-A LMCA-MCH-21-A Multifamily Dwelling Leakage | §120.1(b)2Aivb2 | ATT | |

Mechanical | NRCA-MCH-22-A LMCA-MCH-22-A Multifamily Duct Leakage | ATT | ||

Mechanical | NRCA-MCH-23-A LMCA-MCH-23-A Multifamily HRV/ERV Verification | ATT | ||

Indoor Lighting | NRCA-LTI-02-A LMCA-LTI-02-A Lighting Controls | ATT | ||

Indoor Lighting | NRCA-LTI-03-A LMCA-LTI-03-A Automatic Daylighting Controls | ATT | ||

Indoor Lighting | NRCA-LTI-04-A LMCA-LTI-04-A Demand Responsive Lighting and Receptacle Controls | ATT | ||

Indoor Lighting | NRCA-LTI-05-A LMCA-LTI-05-A Institutional Tuning Power Adjustment Factor | §140.6(a)2J, §170.2(e)Bx | ATT | |

Outdoor Lighting | NRCA-LTO-02-A LMCA-LTO-02-A Outdoor Lighting Acceptance Tests | ATT | ||

Covered Process, Systems, and Equipment | NRCA-PRC-01-F Compressed Air | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-02-F LMCA-PRC-02-F Kitchen Exhaust | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-03-F LMCA-PRC-03-F Garage Exhaust | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-04-F Refrigerated Warehouse –Motor Controls | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-05-F Refrigerated Warehouse – Evaporator | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-06-F Refrigerated Warehouse –Condenser Controls | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-07-F Refrigerated Warehouse – Compressor | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-08-F Refrigerated Warehouse –Underslab Heating | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-12-F LMCA-PRC-12-F Elevator Lighting and Ventilation | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-13-F Escalator Speed | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-14-F Lab Exhaust | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-15-F Fume Hood | §140.4(c)4 | NONE | |

Covered Process, Systems, and Equipment | NRCA-PRC-16-F Adiabatic Condenser | NONE | ||

Covered Process, Systems, and Equipment | NRCA-PRC-17-F FDD System and Steam Trap Strainer Installation Acceptance Test | NA7.21 | NONE |

Source: California Energy Commission

The following provides a summary of the acceptance testing requirements and testing procedures in the Energy Code for mechanical systems, lighting controls, building envelope, and covered processes.

Separate files providing detailed instructions on how to conduct acceptance tests are located at the CEC website: https://www.energy.ca.gov/programs-and-topics/programs/building-energy-efficiency-standards/2022-building-energy-efficiency/.

Envelope acceptance testing may be performed by any field technician however the installing contractor typically performs this testing.

Envelope acceptance testing is required for all buildings except single-family buildings per §110.6(a). These requirements apply to newly constructed buildings and to alterations.

The building envelope acceptance testing procedures are specified in Reference Nonresidential Appendix NA7.4.

The building envelope features that require acceptance testing include:

These tests are required for newly installed fenestration, window film, and dynamic glazing in new construction, additions, and alterations for all buildings except single-family residential per §110.6(a).

These fenestration products must be tested according to NA7.4 to verify that the National Fenestration Rating Council (NFRC) Label Certificate or California CEC Fenestration Certificate is provided for each fenestration product being installed. These certificates identify the thermal performance of the fenestration product (e.g. U-factor, solar heat gain coefficient, and visible transmittance).

This test also verifies that the thermal performance of installed fenestration products match the label certificate, energy compliance documentation, and plan specifications.

These tests are required to qualify for power adjustment factors for clearstory fenestration, interior and exterior horizontal slats, and interior and exterior light shelves in nonresidential, hotel/motel, multifamily common use areas per §140.3(d), §140.6(a)2L, §170.2(e)2xii, and §110.6(a)6.

These daylighting design features must be tested according to NA7.4 to verify that clerestory windows, interior and exterior horizontal slats, and interior and exterior light shelves meet the daylighting design requirements in the Energy Code when claiming a power adjustment factor (PAF) for lighting systems in nonresidential and hotel/motel buildings and multifamily building common use areas.

Spaces that have clerestory windows, horizontal slats, or light shelves, and compliant automatic daylighting controls may receive a power adjustment factor if the daylighting feature meets the design criteria in Energy Code.

This test (NA7.5.1) ensures the constant volume air handling unit provides adequate outdoor air ventilation to the spaces served under all operating conditions. Systems requiring demand ventilation controls per §120.1(c)3 must conform to §120.1(c)4E regarding the minimum ventilation rate when the system is in occupied mode. Related acceptance tests for these systems include the following:

-

NA7.5.2 Constant-Volume, Single-Zone, Unitary Air Conditioners and Heat Pump Systems Acceptance

-

NA7.5.4 Air Economizer Controls Acceptance (if applicable)

-

NA7.5.5 Demand-Controlled Ventilation Systems Acceptance (if applicable)Text

This test is restricted to certified Mechanical ATTs only, using Certificate of Acceptance NRCA-MCH-02-A.

This acceptance test (NA7.5.2) is meant for constant volume, single zone, unitary (packaged and split) air conditioner and heat pump systems. This test verifies the components of a constant volume, single-zone, unitary air conditioner and heat pump system function correctly, including: thermostat installation and programming, supply fan, heating, cooling, and damper operation. Testing of the economizer, outdoor air ventilation, and demand-controlled ventilation are located in the following sections of the Reference Appendices:

-

NA7.5.1.2 Constant Volume System Outdoor Air Acceptance

-

NA7.5.4 Air Economizer Controls (if applicable)

-

NA7.5.5 Demand Control Ventilation (DCV) Systems (if applicable)

This test is restricted to certified Mechanical ATTs only, using Certificate of Acceptance NRCA-MCH-03-A.

This test (NA7.5.3) verifies all duct work associated with all nonexempt constant volume, single-zone HVAC units (in other words, air conditioners, heat pumps, and furnaces) meet the material, installation, and insulation R-values per §120.4(a) and leakage requirements outlined either in §120.4(g)1 for new duct systems or §141.0(b)2D and §141.0(b)2Eii) for existing duct systems.

This test may either be verified by a HERS Rater (sampling permitted) with the technician testing each installation and using NRCA-MCH-04a-H to record the results or performed by a certified mechanical ATT (no sampling permitted) using NRCA-MCH-04b-A and recording it with an ATTCP.

This test (NA7.5.4) is restricted to certified mechanical ATTs and is intended to verify Energy Code compliance for nonresidential and hotel/motel (see NRCA-MCH-23-A for multi-family) buildings with newly installed economizers, dedicated outdoor air system (DOAS), Heat Recovery Ventilation (HRV) systems, and energy recovery ventilation (ERV) system. Economizers must be certified to the California CEC in compliance with JA6.3

Submit one Certificate of Acceptance (NRCA-MCH-05-A) for each economizer, DOAS, HRV, or ERV system that must demonstrate compliance with the Energy Code. For direct Energy Code reference see JA6.3, NA7.5.4, §140.4(e), §120.5(a)4, and §160.3(d)1D.

Functionally testing an air economizer cycle verifies that an HVAC system uses outdoor air to satisfy space-cooling loads. There are two types of economizer controls: stand-alone packages and DDC controls. The stand-alone packages are commonly associated with small unitary rooftop HVAC equipment. DDC controls are typically associated with built-up or large packaged air handling systems.

Cooling fan systems greater than 33,000 Btu/hr may use an economizer to comply with prescriptive requirements in §140.4(e). Air economizers must be able to provide 100 percent of the design supply air with outside air; water economizers must be able to provide 100 percent of the design n cooling load at 50°F dry-bulb and 45°F wet-bulb.

The purpose of the test (NA7.5.5) is to verify that systems required to employ demand controlled ventilation (refer to §120.1(c)3) can vary outside ventilation flow rates based on maintaining interior carbon dioxide (CO2) concentration setpoints. Demand Ventilation Control (DVC) refers to an HVAC system’s ability to reduce outdoor air ventilation flow below design values when the space served is at less than design occupancy.CO2 is a good indicator of occupancy load and is the basis used for modulating ventilation flow rates.

DVC complying with §120.1(d)4 are required for a space with a design occupant density, or a maximum occupant load factor for egress purposes in the CBC, greater than or equal to 25 people per 1000 square feet (40 square feet or less per person) if the ventilation system serving the space has one or more of the following:

-

an air economizer, modulating outside air control, or

-

design outdoor airflow rate > 3,000 cfm (§120.1(d)3).

This acceptance test is limited to certified mechanical ATTs using NRCA-MCH-06-A to verify that a system required to employ a DVC can vary outside air ventilation flow rates based on maintaining interior carbon dioxide (CO2) concentration setpoints in compliance with §120.1(d)4. NRCA-MCH-02-A must be completed either prior to or concurrently with this acceptance test for the space in which the CO2 monitor is located. One NRCA-MCH-06-A must be completed for each CO2 sensor in the system that must demonstrate compliance. For direct Energy Code reference see §120.1(d)3, §120.1(d)4, NA7.5.1, and NA7.5.5.

The purpose of the test (NA7.5.6) is to ensure that the supply fan in a variable air volume application modulates to meet system airflow demand. In most applications, the individual variable air valve (VAV) boxes serving each space will modulate the amount of air delivered to the space based on heating and cooling requirements. As a result, the total supply airflow provided by the central air handling unit must also vary to maintain sufficient airflow through each VAV box. Airflow is typically controlled using a variable frequency drive (VFD) to modulate supply fan speed and vary system airflow. The most common strategy for controlling the VFD is to measure and maintain static pressure within the duct.

This test is restricted to a certified mechanical ATT using NRCA-MCH-07-A to verify that the supply fan speed in a variable air volume system modulates to meet system airflow demand. NRCA-MCH-07-A can be performed in conjunction with NRCA-MCH-02-A Outdoor Air Acceptance since testing activities overlap.

This test (NA7.5.7) ensures that control valves serving variable flow systems are designed to withstand the pump pressure over the full range of operation. Valves with insufficient actuators will lift under certain conditions causing water to leak and loss of flow control. This test applies to the variable flow systems covered by §140.4(k)1 chilled and hot-water variable flow systems, §140.4(k)2 chiller isolation valves, §140.4(k)3 boiler isolation valves, and §140.4(k)5 water-cooled air conditioner and hydronic heat pump systems.

This test is restricted to certified mechanical ATTs using NRCA-MCH-08-A to ensure that control valves serving variable flow systems can withstand the pump pressure over the full range of operation. Related acceptance tests for these systems include NA7.5.9 Hydronic System Variable Flow Controls Acceptance Testing time will be greatly reduced if these acceptance tests are done simultaneously.

This test (NA7.5.8) ensures that both the chilled water and hot water supply temperatures are automatically reset based on either building loads or outdoor air temperature, as indicated in the control sequences. Many HVAC systems are served by central chilled and heating hot water plants. The supply water operating temperatures must meet peak loads when the system is operating at design conditions. As the loads vary, the supply water temperatures can be adjusted to satisfy the new operating conditions. Typically the chilled water supply temperature can be raised as the cooling load decreases, and heating hot water supply temperature can be lowered as the heating load decreases.

This requirement only applies to chilled and hot water systems that are not designed for variable flow and that have a design capacity greater than or equal to 500 kBtuh (thousand BTU’s per hour), according to §140.4(k)4 .

This test is restricted to certified mechanical ATTs using NRCA-MCH-09-A to ensure that both the chilled water and hot water supply temperatures are automatically reset based on either building loads or outdoor air temperature, as indicated in the control sequences. (§140.4(k)4).

Note the following exception: Hydronic systems that use variable flow to reduce pumping energy. (§140.4(k)1)

This test (NA7.5.9) is for all hydronic variable flow chilled water and water-loop heat pump systems with total circulating pump power larger than 5 hp shall vary system flow rate by modulating pump speed using either a variable frequency drive (VFD) or equivalent according to §140.4(k)6 . Pump speed and flow must be controlled as a function of differential pressure, and pump motor demand must be no more than 30 percent design wattage at 50 percent design flow.

As the loads within the building fluctuate, control valves should modulate the amount of water passing through each coil and add or remove the desired amount of energy from the air stream to satisfy the load. In the case of water-loop heat pumps, each two-way control valve associated with a heat pump closes when not operating. The purpose of the test is to ensure that, as each control valve modulates, the pump variable frequency drive (VFD) responds accordingly to meet system water flow requirements.

This test is restricted to certified mechanical ATTs using NRCA-MCH-10-A to ensure that hydronic pump speed varies with building heating and cooling loads. The related acceptance tests for this system is NA7.5.7 Valve Leakage Test – NRCA-MCH-08-A (if applicable)

This test (NA7.5.10) is used if the building has DDC to the zone level, the HVAC control system must be capable receiving a Demand Response Signal and automatically initiating a control strategy once the signal is received. This acceptance test confirms that the HVAC control system is programmed so that it is capable of initiating the control strategy specified in §110.12(b). That is, modify the temperature setpoints in non-critical zones up by 4oF if the system is cooling the space or down by 4oF if the system is heating the space. The building owner or occupant has the option of selecting another control strategy than the one tested here if they choose to enroll in a demand response program.

This test is restricted to certified mechanical ATTs using NRCA-MCH-11-A to ensure that the central demand shed sequences have been properly programmed into the DDC system.

The purpose of this test (NA7.5.11) is to verify proper fault detection and diagnostic (FDD) reporting for automated fault detection and diagnostics systems for packaged DX units. Automated FDD systems ensure proper equipment operation by identifying and diagnosing common equipment problems such as temperature sensor faults, low airflow or faulty economizer operation. FDD systems help to maintain equipment efficiency closer to rated conditions over the life of the equipment.

This test is restricted to certified mechanical ATTs use NRCA-MCH-12-A and is recommended to be performed simultaneity with NRCA-MCH-02-A (Outside Air) and NRCA-MCH-05-A (Air Economizer Controls).

The purpose of this test (NA7.5.12) is to verify proper FDD reporting for air handling unit (AHU) and zone terminal unit (ZTU) systems. Fault detection and diagnostics can also be used to detect common faults with air handling units and zone terminal units. Many FDD tools are standalone software products that process trend data offline. Maintenance problems with built-up air handlers and variable air volume boxes are often not detected by energy management systems because the required data and analytical tools are not available. Performing the FDD analysis within the distributed unit controllers is more practical because of the large volume of data.

The acceptance tests are designed to verify that the system detects common faults in air handling units and terminal units. FDD systems for air handling units and zone terminal units require DDC controls to the zone level. Successful completion of this test provides a compliance credit when using the performance approach. An FDD system that does not pass this test may still be installed, but no compliance credit will be given.

This test is restricted to certified mechanical ATTs use NRCA-MCH-13-A to verify that the system detects common faults in air handling units and zone terminal units.

This test (NA7.5.13) verifies proper operation of distributed energy storage DX systems. Distributed energy systems reduce peak demand by operating during off peak hours and storing cooling, usually in the form of ice. During peak cooling hours the ice is melted to avoid compressor operation.

This acceptance test applies to direct expansion (DX) system with distributed energy storage (DES/DXAC). These acceptance requirements are in addition to those for those other systems or equipment such as economizers or packaged equipment. This acceptance test was developed by AEC for Distributed Energy Storage for Direct-Expansion Air Conditioners, January 27, 2005, and is directly referenced by the 2022 Building Energy Efficiency Standards.

This test is restricted to certified mechanical ATTs use NRCA-MCH-14-A to verify that the system conforms with the Energy Code requirements.

This test (NA7.5.14) verifies proper operation of thermal energy storage (TES) systems. TES systems reduce energy consumption during peak demand periods by shifting energy consumption to nighttime. Operation of the thermal energy storage compressor during the night produces cooling energy, which is stored in the form of cooled fluid or ice in tanks. During peak cooling hours the thermal storage is used for cooling to prevent the need for chiller operation.

The test will ensure that the TES system is able to charge the storage tank during off-peak hours and conversely discharge the storage tank during on peak hours. Since the chiller may operate more efficiently at night when ambient temperatures are lower, the system may save cooling energy in some climate zones. This acceptance test is intended for Thermal Energy Storage (TES) Systems that are used in conjunction with chilled water air conditioning systems.

This test is restricted to certified mechanical ATTs use NRCA-MCH-15-A to verify that the system conforms with the Energy Code requirements.

The purpose of the test (NA7.5.15) is to ensure that the supply air temperature in a constant or variable air volume application serving multiple zones, according to Section 140.4(f), modulates to meet system heating and cooling loads. Space conditioning systems must have zone level controls to avoid reheat, re-cool, and simultaneous cooling and heating [§140.4(d)]; or must have controls to reset supply air temperature (SAT) by at least 25 percent of the difference between the design supply-air temperature and the design room air temperature [§140.4(f)2 ]. Air distribution systems serving zones with constant loads must be designed for the air flows resulting from the fully reset (e.g. lowest/highest) supply air temperature. The requirements for SAT reset apply to both CAV and VAV systems. Exceptions include:

-

Systems with specific humidity needs for exempt process loads (computer rooms or spaces serving only IT equipment are not exempt).

-

Zones served by space conditioning systems in which at least 75 percent of the energy for reheating, or providing warm air in mixing systems, is provided from a site-recovered or site-solar energy source.

-

Systems in which supply air temperature reset would increase overall building energy use.

-

Systems with controls to prevent reheat, re-cool, and/or simultaneous cooling and heating.

Supply air temperature may be reset in response to building loads, zone temperature, outside air temperature, or any other appropriate variable.

This test is restricted to certified mechanical ATTs use NRCA-MCH-16-A to verify that the supply air temperature modulates to meet system temperature setpoint(s).

The intent of the test (NA7.5.16) is to verify that the condenser water supply (entering condenser water) temperature is automatically reset as indicated in the control sequences; based upon building loads, outdoor air wet-bulb temperature, or another appropriate control variable. All cooling tower system components (e.g. fans, spray pumps) should operate per the control sequences to maintain the proper condenser water temperature and pressure set points.

Chilled water plants serve many buildings, responding to the varying cooling loads throughout the year. As the loads vary, the chilled water supply temperatures adjust to satisfy the new operating conditions. Often, water-cooled chilled water plants can decrease the condenser water temperature in times of low cooling load. This occurrence can be demonstrated by running the cooling tower fans at a higher speed, staging on additional fans, or varying water distribution across the tower fill by closing and opening bypass valves. As a result, the cooling tower produces an energy penalty, however the chiller efficiency and the overall plant efficiency improves.

The purpose of this test is not to evaluate whether a particular control sequence is the most appropriate for the facility, but whether the system follows the intended control sequence. This test is restricted to certified mechanical ATTs use NRCA-MCH-17-A to ensure that the condenser water supply temperature is automatically reset as indicated in the control sequence(s).

The purpose of this acceptance test (§120.5(a)17 and §160.3(d)1P) is to ensure that when an energy management control system (EMCS) is installed for the purpose of compliance with the Building Energy Efficiency Standards (Standards), it is properly installed, operational, and is in compliance with each relevant requirement in the Standards.

This test is restricted to certified mechanical ATTs use NRCA-MCH-18-A to ensure that when an energy management control system (EMCS) is installed for the purpose of compliance with the Energy Code, it is properly installed, operational, and is in compliance with each relevant requirement in the Standards.

This test (NA7.5.17) verifies that an installed occupancy sensor is functional and in compliance with the approved project designs and Energy Code. The technician must submit one Certificate of Acceptance for each occupancy sensor installed.

This test is restricted to certified mechanical ATTs use NRCA-MCH-19-A to ensure that the occupancy sensor is functional and in compliance with the design and with the Energy Code.

This test (NA7.18.1) can be performed by a certified mechanical ATT or uncertified technician and HERS Rater to verify that the continuous ventilation airflow (supply, exhaust, or balanced) system, the kitchen exhaust fan, and/or the heat recovery ventilations (HRV) or energy recovery ventilation (ERV) system conforms to the requirements of the Energy Code and ANSI/ASHRAE Standards 62.2-2016. If using supply-only or exhaust-only ventilation, Certificate of Acceptance NRCA-MCH-21-H must be completed prior to beginning this acceptance test.

This test is not restricted to certified mechanical ATTs if a HERS Rater is used as a verification for an uncertified technician to perform the same test and the verification is registered with a HERS Provider. Alternatively, these same forms can be used by a mechanical ATT without need of a HERS Rater.

NRCA-MCH-20a-H must be completed (once) for all of the subsequent forms for dwelling ventilation requirements. NRCA-MCH-20b-H is used to verify the kitchen range hood complies with the Energy Code requirements. NRCA-MCH-20c-H is used to verify the indoor air quality ventilation systems complies with the Energy Code requirements. NRCA-MCH-20d-H is used to verify HRV or ERV (if installed) systems comply with the Energy Code requirements.

This acceptance test is intended for multifamily dwelling units where CONTINUOUS ventilation is used. The Executive Director may approve INTERMITTENT mechanical ventilation systems, devices, or controls for use for compliance with field verification and diagnostic testing requirements for mechanical ventilation airflow, subject to a manufacturer providing sufficient evidence to the Executive Director that the installed mechanical ventilation systems, devices, or controls will provide at least the minimum ventilation airflow required by the Standards, and subject to consideration of the manufacturer's proposed field verification and diagnostic test protocol for the ventilation system(s). Ventilation airflow of systems with multiple operating modes shall be tested in all modes designed to comply with the required ventilation airflows. Approved systems, devices, or controls, and field verification and diagnostic test protocols for intermittent mechanical ventilation systems will be listed in directories published by the CEC (NA2.2.4.1.3).

This acceptance test (NA7.18.2) is used to verify that the envelope leakage rate for multifamily dwelling units conforms to the requirements of the Energy Code.

This test is not restricted to certified mechanical ATTs if a HERS Rater is used as a verification for an uncertified technician to perform the same test and the verification is registered with a HERS Provider. Alternatively, this same form can be used by a mechanical ATT without need of a HERS Rater.

NRCA-MCH-21-H must be completed for each dwelling unit using a supply-only or exhaust-only ventilation system to verify that the envelope leakage conforms to the requirements of the Energy Code §120.1(b)2Aivb2 and Nonresidential Reference Appendices NA7.18.2, NA2.3, ANSI/RESNET/ICC 380-2016, and ASTM E779-10 (2010). The certified mechanical ATT or technician and HERS Rater is required to complete this compliance certificate prior to completing NRCA-MCH-20-H.

See section 14.3.2.19 regarding intermittent ventilation systems.

The objective of this procedure (NA7.18.3) is to verify the leakage of a new central ventilation duct system(s) 160.2(b)2Ci) that serve multiple dwelling units and provides continuous airflows or are part of a balanced ventilation system to meet the requirements specified in Sections 160.2(b)2Aiv or 160.2(b)2Av. This compliance document (NRCA-MCH-22-A) is used to record the results of one system duct leakage test performed. These test procedures are based on ATSM 1554 Method D – Total duct leakage test. This test may only be performed by a certified mechanical ATT.

The objective of this acceptance test is to verify the HRV or ERV requirement in multifamily buildings for compliance with Section 170.2(c)3Bvb, a central ERV/HRV serving multiple dwelling units. This test may only be performed by a certified mechanical ATT.

Lighting controls acceptance testing must be performed by a certified lighting controls ATT to certify the indoor and outdoor lighting controls serving the building, area, or site meet the acceptance requirements.

Lighting controls acceptance testing is required for all installed lighting controls in nonresidential buildings and hotel/motel buildings per §130.4(a), and for multifamily building common use areas per §160.5(e) . These requirements apply to newly constructed buildings and to alterations. For alterations where lighting controls are added to control 20 or fewer luminaires, acceptance testing is not required.

The lighting controls acceptance testing procedures are specified in Reference Nonresidential Appendix NA7.6.

The lighting controls that require acceptance testing include:

This test is required when automatic daylighting controls are installed in nonresidential and hotel/motel buildings or in multifamily building common use areas. General lighting within a daylit zone must be controlled by automatic daylighting controls per the requirements of §130.1(d) and §160.5(b)4D.

Automatic daylighting controls must be tested according to NA7.6.1 to verify that the automatic daylighting controls are installed and that they automatically adjust electric lighting power in response to available daylighting in the space.

All installed indoor lighting must be controlled by shutoff controls per §130.1(c) and §160.5(b)4C. Shutoff controls acceptance testing ensure that occupant sensing controls and automatic time switch controls that are installed are functioning according to these requirements.

Automatic shutoff controls must be tested according to NA7.6.2 to verify that occupant sensing controls and automatic time switch controls are functioning properly to achieve the desired lighting controls.

Occupant sensing control acceptance testing verifies that the controls are installed per manufacturer’s instructions and that the occupant sensing control dims or turns lighting on or off according to occupancy in the space.

The automatic time switch controls acceptance testing verifies that indoor lighting controlled by an automatic time switch control turns lighting on and off according to a programmed schedule and that manual override controls turn lighting on during scheduled off periods.

This test is required when demand responsive lighting controls are installed in nonresidential and hotel/motel buildings, and in multifamily building common areas per the requirements of §130.1(e), §160.5(b)4E, and §110.12. Demand responsive lighting controls are required for:

-

Newly constructed buildings with general lighting power of 4,000 watts or greater

-

Lighting alterations and additions with general lighting power of 4,000 watts or greater

Demand responsive lighting controls must be tested according to NA7.6.2 to verify that demand responsive controls can reduce lighting power of the building to at least 85 percent of full power. The test also confirms that the lighting system produces a uniform level of illumination during a demand response event.

This test is required when institutional tuning controls are installed to qualify for a power adjustment factor in nonresidential and multifamily common use area lighting systems per §140.6(a)2J or §170.2(e)2Bx. Institutional tuning is the process of adjusting the maximum light output of lighting systems to support visual needs or save energy. Institutional tuning differs from personal tuning in that the control strategy is implemented at the institutional rather than the individual user level, and maximum light level adjustments are available only to authorized personnel.

Institutional tuning must be tested according to NA7.6.4 to verify that the institutional tuning controls limit the maximum light output or power draw of the controlled lighting to 85 percent or less of full light output or full power draw.

Completion of this acceptance test certifies that lighting systems receiving the institutional tuning power adjustment factor (PAF) comply with §140.6(a)2J or §170.2(e)2Bx, and NA7.6.4.

This test is required when demand responsive controls for controlled receptacles are installed in nonresidential and hotel/motel buildings, and in multifamily building common use areas per the requirements in §130.5(d), §160.6(e), and §110.12(e). Demand responsive controls for controlled receptacles are required in when the following conditions are met:

Demand responsive controls for controlled receptacles must be tested according to NA7.6.5 to verify that demand responsive controls can turn off all loads connected to controlled receptacles when a demand response signal is received.

This test applies to outdoor lighting controls which include photocontrols, motion sensors, astronomical time-switch controls, and scheduling controls for outdoor lighting systems per the requirements of §130.2 and §160.5(c). These controls are required for nonresidential, hotel/motel, and multifamily buildings.

Outdoor lighting controls must be tested according to NA7.8 to verify that all outdoor lighting regulated by §130.2(c) and §160.5(c) is controlled by a motion sensor, photocontrol, astronomical time-switch control, and automatic scheduling control, as required.

Covered process acceptance testing may be performed by any field technician however the startup technician typically performs this testing.

Covered process acceptance testing is required for all covered process specified in §120.6 and §140.9. These requirements apply to newly constructed buildings and to alterations.

The covered process acceptance testing procedures are specified in Reference Nonresidential Appendix NA7.10 through NA7.20.

The covered processes that require acceptance testing include:

-

NA7.10 Refrigerated warehouse refrigeration systems

-

NA7.11 Commercial kitchen exhaust systems

-

NA7.12 Parking garage ventilation systems

-

NA7.13 Compressed air systems

-

NA7.14 Elevator lighting and ventilation controls

-

NA7.15 Escalator and moving walkway controls

-

NA7.16 Lab exhaust ventilation systems

-

NA7.17 Fume hood automatic sash closure

-

NA7.19 Steam trap fault detection

-

NA7.20 Transcritical CO2 systems

New refrigerated warehouses, or new refrigeration system serving a refrigerated warehouse require acceptance testing per §120.6(a). The following equipment and systems must be tested to verify that the system operates according to Energy Code requirements.

-

Electric resistance underslab heating systems must be tested according to NA7.10.1 to verify that any heated slab that uses an electric resistance heating system is thermostatically controlled to prevent excess heat from entering the refrigerated space and that its load is shed during the summer on-peak period defined by the electric utility provider, as required per Energy Code. The test verifies that the electric resistance heater is controlled according to the underfloor temperature and is forced off during the summer on-peak period.

-

Evaporators and evaporative fan motor controls must be tested according to NA7.10.2 to verify that evaporator fans modulate speed in response to space temperature or humidity. Evaporator fan motor controls are required for new, or altered refrigerated warehouses that are 3,000 square feet or more and refrigerated spaces with a sum total of 3,000 square feet that are served by the same refrigeration system

-

Evaporative, air-cooled, and adiabatic condensers must be tested according to NA7.10.3 to verify that the condensing temperature setpoint of the condenser is reset in response to ambient dry-bulb or wet-bulb temperature, condenser fan speed is continuously variable, condenser fans are controlled in unison, and that the minimum condensing temperature control setpoint meets specifications. Condenser fan motor controls are required on any new evaporative, air-cooled, or adiabatic condensers installed on new refrigeration systems.

-

Variable speed compressors must be tested according to NA7.10.4 to verify that variable speed compressor controls modulate compressor speed in response to the refrigeration load. Compressor variable speed controls are required on any new refrigeration systems.

New commercial kitchens, or new commercial kitchen exhaust systems with Type I and Type II kitchen hood exhausts with a total exhaust airflow rate greater than 5,000 cfm require acceptance testing per §140.9(b).

All Type I exhaust hoods must be tested according to NA7.11 to verify that the exhaust airflow rate meets Energy Code requirements, and that demand control ventilation, and make up air systems are functional.

All new compressed air systems, and all additions or alterations of compressed air systems, where the total combined online horsepower of the compressor(s) is 25 horsepower or more, must be tested per §120.6(e).

Compressed air system controls must be tested according to NA7.13 to verify that compressed air system controls and monitoring systems are set up in a compliant manner. A compliant system will use the most efficient combination of compressors, given the current air demand as measured by a sensor. This test ensures that short-cycling or blow-off does not occur. For new compressed air systems, the trim compressors are the only compressors that can be partially loaded. All base compressors must be either fully loaded or off by the end of the test.

This test is required for newly installed elevators in nonresidential, multifamily, and hotel/motel buildings per §120.6(f).

Elevator lighting and ventilation controls must be tested according to NA7.14 to verify that shut off controls installed in an elevator cab turn lighting and ventilation fans off when the elevator is not occupied for more than 15 minutes, and on when elevator cab operation resumes.

The control system must also be able to detect occupancy, and keep the lighting and ventilation fan on, in the event that someone is occupying the elevator cabin and the elevator conveyance or doors malfunction.

This test is required for newly installed escalators and moving walkways located in airports, hotels, and transportation function areas per §120.6(g).

Escalator and moving walkway controls must be tested according to NA7.15 to verify that the speed of the escalator or moving walkway slows when unoccupied and speeds up when passengers approach. The control system must be able to detect occupancy and approaching pedestrians in either direction.

This test is required for newly installed laboratory and factory exhaust systems with airflow greater than 10,000 cfm per §140.9(c).

Lab exhaust and ventilation controls must be tested according to NA7.16 to verify that the design and installation of the laboratory exhaust system, including wind speed and contaminant controls, are installed and in operation to limit excessive energy use, without sacrificing operator safety.

This test is required for newly constructed laboratory fume hoods with vertical only sashes, located in fume hood intensive laboratories per §140.9(c)4.

Fume hood automatic sash closure controls must be tested according to NA7.17 to verify that the manual and automated controls of the fume hood and sash operate in compliance with the Energy Code and the enforcement agency approved design.

This test is required for steam traps in new industrial facilities and new steam traps added to support new, non-replacement, process equipment in existing industrial facilities where the following conditions are met:

- The installed steam trap operating pressures is greater than 15 psig

- The total combined connected boiler input rating is greater than 5 million Btu per hour

Requirements for steam trap fault detection are included in §120.6(i).

Steam trap fault detection must be tested according to NA7.19 to verify that the fault detection system is installed, programmed, and operating in compliance with the Energy Code.

This test is required for all new refrigerated warehouses and retail food or beverage stores with transcritical CO2 refrigeration systems, or for newly installed transcritical CO2 refrigeration systems serving refrigerated warehouses and retail food or beverage stores per §120.6(a) and §120.6(b).

Transcritical CO2 refrigeration systems must be tested according to NA7.20 to verify proper operation of gas cooler control, including variable speed fan operation and variable setpoint control logic, which are both important elements of floating head pressure control, with the intent to operate with the lowest total system energy (considering both compressors and gas cooler fan power) through the course of the year.

- No changes

- New Acceptance Test:

- Central Ventilation System Duct Leakage Acceptance for multifamily projects

- Central Ventilation System HRV or ERV for multifamily projects

- Major Modifications:

- All acceptance test form were updated to comply with accessibility requirements.

- Acceptance test for DOAS, HRV, ERV added to economizer acceptance test (NA7.5.4)

- ATT as an alternative to the technician-HERS Rater verification process was added as an option to four acceptance tests for multifamily low-rise projects:

- Dwelling Unit Ventilation

- Indoor air quality airflow (supply, exhaust, or balanced) system

- Kitchen exhaust fan

- DOAS, HRV, or ERV system

- Multifamily Envelope Leakage

- Minor Clarifications

- Revised references to reflect the new multifamily section in the Energy Code.

- New Acceptance Tests:

- Demand responsive controlled receptacles (NA7.6.5, NRCA-LTI-04-A)

- Major Modifications:

- Lighting controls installed in multifamily common use areas require acceptance testing per §160.5(e) .

- An alternative partial daylight test has been added to address stakeholder concerns with the feasibility of using the current partial daylight test in all conditions, particularly in daylit spaces with dark glazing or small window areas (NA7.6.1.4).

- An alternative demand responsive controls testing procedure has been added to allow testing for the entire facility at once provided that the lighting load is disaggregated from other end use loads (NA7.6.3.2.3).

- A new testing procedure has been added for multi-zone occupant sensing controls in offices larger than 250 square feet (NA7.6.2.4).

- Addition of sampling procedures for outdoor photocontrols acceptance testing (NA7.8.3.2).

- Minor Clarifications:

- Added specific items to verify during the construction inspection to improve clarity and align with Energy Code requirements

- Reorganize testing procedure steps to improve clarity and align testing procedures with how testing is conducted in the field.

- Added clarification on testing procedures for partial on, partial off, and vacancy sensing controls.

- New Acceptance Tests:

- Major Modifications: None.

- Minor Clarifications: None.

The requirements to become either a nonresidential lighting controls or mechanical Acceptance Test Technician Certification Provider (ATTCP) are very similar. Therefore, this section will address both the lighting controls and mechanical ATTCP application requirements together, calling out specific differences when warranted. The prospective ATTCP must submit a written application to the CEC that documents the following major elements:

ATTCPs shall provide written explanations of the organization type, bylaws, and ownership structure. ATTCPs shall explain in writing how their certification program meets the qualification requirements of §10-103.1(c) (or §10-103.2(c)). ATTCPs shall explain in their application to the CEC their organizational structure and their procedures for independent oversight, quality assurance, supervision and support of the acceptance test training, and certification processes (§10-103.1(c)1 and §10-103.2(c)1).

This requirement is necessary to ensure, at a minimum, that the organizations providing certification services to the building industry have a business structure that is conducive to train, certify, and oversee ATTs.

The CEC has approved several ATTCP applicants, and all applications included articles of incorporation, bylaws, and trust agreements. One approved application included the Section 501(c) status (with the corresponding employer identification number) of the organization. A copy of the ethics policy for the ATTCP is recommended.

This section of the application should also include a description of how the organization is conducive to providing training, certification, oversight, and support to the technicians that they will be certifying. The ATTCP may also describe what qualifications and experience the ATTCP may have to operate and oversee an accreditation program.

The ATTCPs shall provide written explanations of their certification and oversight of acceptance test employers (ATEs) that employ ATTs. This explanation shall document how the ATTCP ensures that the ATEs are providing quality control and appropriate supervision and support for their ATTs (§10-103.1(c)2 and §10-103.2(c)2).

The ATTCP shall recertify all ATEs before implementing each adopted update to the Energy Code as these updates affect the acceptance test requirements. Recertification requirements and procedures shall only apply to those specific elements that are new or modified in future updates to Energy Code.

ATEs must have an understanding of what tasks the ATT is responsible to complete. Moreover, the ATE must manage and provide support to the ATTs in performing their tasks. The ATTCP is required to describe the training and requirements that they will place on the ATE for these endeavors and issue certificates to qualified ATE applicants. The requirement for the ATEs to be retrained for each new code cycle is intended to maintain the current educational level of the ATEs. The quality control that the ATEs provide to the ATTs is different from the quality control that the ATTCPs provide.

The CEC recognizes that there are many roads to compliance regarding ATE training, certification, and oversight. Technical training typically consists of 4 to 24 hours of instruction. Quality control, supervision, and support requirements implemented by the ATTCP on the ATE can vary considerably. Some elements that the ATTCP might consider implementing, but that are not specifically required by the CEC regulations, include the following:

- The ATTCP may develop a policy to address where a change in employment results in no ATE manager or supervisor having completed the ATE training.

- The ATTCP may adopt an ethics policy for ATEs.

- Union contracting requirements: The ATTCP may be restricted to serving unionized technicians only and as a result the ATTCP may require that the ATE be a party in good standing with a union contract. This may entail several significant requirements for the ATE.

- Third-party certificate holders: The ATTCP may require that the ATE hold a valid certificate from a third party, such as specific types of testing and air balancing (TAB) training.

- Multiple office management requirements: The ATTCP may consider how it will implement ATE training and certification requirements where an ATE has multiple offices. The ATTCP may consider requiring that an ATE with multiple offices shall ensure a middle or senior management level employee at each office has completed the ATE certification training.

- Restrictive employment practices: The ATTCP may restrict the ATE from employing an ATT that is certified by a different ATTCP. Furthermore, the ATTCP may restrict the ATE from holding certificates from multiple ATTCPs.

- Licensing, insurance, and safe practices requirements: The ATTCP may require the ATE to provide initial and ongoing proof of workers’ compensation and general liability insurance (typically a minimum dollar amount is specified), local business licenses, injury and illness prevention program, and Code of Safe Practices (typically required to be consistent with the California Code of Regulations, Sections 1509 and 3203).

- Equipment Policy: The ATTCP may require the ATE to agree to requirements for ensuring that the ATE and ATT possess and properly maintain diagnostic equipment.

These requirements are the most significant of the ATTCP regulations. They encapsulate all the required training, testing, certification, and oversight for the ATTs and ATEs that the ATTCP must provide. These requirements describe the level of experience, education, professionalism, and accountability of the ATT that the CEC is seeking and that the ATTCP must enforce.

ATTCPs shall include with their application a complete copy of all training and testing procedures, manuals, handbooks, and materials. ATTCPs shall explain in writing how their training and certification procedures include, but are not limited to, the following (§10-103.1(c)3 et seq. and §10-103.2(c)3 et seq.):

The ATT training must include both classroom and laboratory training. In essence, the ATT must be instructed on all acceptance tests and then practice those instructions in a laboratory setting. Furthermore, the ATT must be educated on the general science regarding acceptance testing, as well as the procedure to complete and submit the correct acceptance test documents.

- Curricula.

ATTCP training curricula for lighting controls and mechanical ATTs shall include, but not be limited to, the analysis, theory, and practical application of the items listed in §10-103.1(c)3Bi and §10-103.2(c)3Bi, respectively. These include training on the acceptance tests themselves.

Several approved ATTCPs require extensive classroom training to accomplish this educational requirement. One approved ATTCP requires that each ATT applicant hold a third-party certificate of training that the CEC found to be equivalent to the curricula required. - Hands-on training.

The ATTCP shall describe in its application the design and technical specifications of the laboratory boards, equipment, and other elements that will be used to meet the hands-on requirements of the training and certification - Prequalification.

Participation in the certification program shall be limited to persons who have at least three years of professional experience and expertise in either lighting controls and electrical systems or mechanical systems, as determined by the ATTCP.

Professional experience is defined by the ATTCP, but generally means experience in a professional occupation that provides training and work experience related to the systems subject to lighting controls or mechanical acceptance testing. The ATTCP must clarify the process that it will use to determine what experience is considered professional and relevant to either lighting controls or mechanical acceptance testing, as well as to what extent the ATTCP will verify that experience. The following are some relevant questions that the ATTCP should consider when establishing an ATT applicant's prequalified experience, though not specifically required by regulation:- • How is the experience documented (for example, letters from employers or other written evidence), and how is it related to lighting controls or mechanical acceptance testing requirements?

- • Should professional experience be demonstrated by requiring applicants to be certified in specifically identified professions, such as:

- o California licensed electrical contractors.

- o California licensed mechanical or HVAC contractors.

- o California certified general electricians.

- o California licensed air conditioning repair contractors.

- o California licensed professional engineers.

- o Lighting control manufacturer representative.

- o Certified commissioning professionals.

- o Other professional occupations that are demonstrated to provide industry- accepted training and work experience relevant to the systems subject to lighting control or mechanical acceptance testing.

- ATTCPs may adopt additional prequalification requirements for ATT applicants. For example, An ATTCP may restrict applicants from participating in the training program if the applicant is decertified by other ATTCPs. Any such additional requirements are at the ATTCP's discretion and not required by the CEC.

- Instructor-to-Trainee Ratio

The ATTCP shall document in its application to the CEC why its instructor-to-trainee ratio is sufficient to ensure the integrity and efficacy of the curriculum and program based on industry standards and other relevant information.

Typically, the instructor-to-student ratio for classroom training is much higher than for laboratory training. In the applications that the CEC has approved, classroom instructor to student ratios were between 1:25 and 1:35. For laboratory training, the ratios were between 1:6 and 1:12. Most important, each ATTCP application included a discussion of the basis for each ratio. - Tests

The ATTCP shall describe the written and practical tests used to demonstrate each certification applicant’s competence in all specified subjects. The ATTCPs shall retain all results of these tests for five years from the date of the test.

When developing and implementing both written and practical tests, the ATTCP may consider the following issues:- • Subject matter experts should validate exams by for content.

- • Pilot testing and statistical analysis by qualified psychometricians can identify poor quality questions and bias, as well as validating a passing score.

- • Checking exam question response option frequency and other measurements of consistency may help validate the exam rigor and justify passing scores and performance standards.

- • Exam questions should be evaluated annually to confirm reliability, rigor, and lack of bias.

- • Lack of bias should be Validated consistent with the Uniform Guidelines on Employee Selection Procedures (1978) Federal Register, 43(166), 38290-38315.

Measures should be adopted to ensure exam security, such as having multiple versions of exams with random question generation and at least twice the number of questions in a validated question bank than are scored on any given test.

vi. Recertification.

The ATTCP shall recertify all ATTs before implementing each adopted update to the Energy Code when these updates affect the acceptance test requirements. Recertification requirements and procedures shall apply only to those specific elements that are new or modified in future updates to the Energy Code.The ATTCP shall develop recertification training curricula for ATTs consistent with training requirements in §10-103.1(c)3A and §10-103.1(c)3B (or §10-103.2(c)3A and §10-103.2(c)3B) and shall submit the proposed recertification training curricula to the CEC for review and approval in the update report required under §10-103.1(d)2 (or §10-103.2(d)2). Once approved, the ATTCP will implement the recertification process.

Training for ATEs shall consist of at least a single class or webinar consisting of at least four hours of instruction that covers the scope and process of the lighting controls or mechanical systems acceptance tests in the Energy Code.

The ATTCPs shall describe in their applications to the CEC procedures for accepting and addressing complaints regarding the performance of any ATT or ATE certified by the ATTCP and explain how building departments and the public will be notified of these proceedings.

The ATTCPs shall describe in their applications to the CEC procedures for revoking their certification of ATTs and ATEs based upon poor quality or ineffective work, failure to perform acceptance tests, falsification of documents, failure to comply with the documentation requirements of these regulations, or other specified actions that justify decertification. The ATTCP shall also describe its general procedures for decertified ATTs or ATEs seeking to regain their certification status, including eligibility requirements for recertification (if any).

The quality assurance and accountability requirements for lighting controls and mechanical ATTCPs vary significantly for the 2022 Energy Code, so they will be discussed separately.

- Lighting Controls

The ATTCP shall describe in its application to the CEC its procedures for conducting quality assurance and accountability activities, including, but not limited to, the following:- The ATTCP shall include quality assurance and accountability measures, including, but not limited to, independent oversight of the certification materials, processes, and procedures; visits to building sites where certified technicians are completing acceptance tests; certification process evaluations; building department surveys to determine acceptance testing effectiveness; and expert review of the training curricula developed for Energy Code §130.4 and §160.5(e).