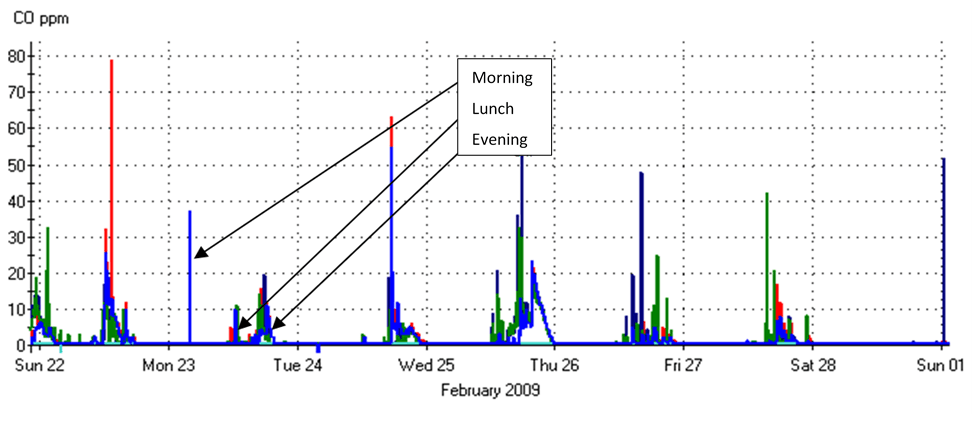

Garage exhaust systems are sized to dilute the auto exhaust at peak conditions to an acceptable concentration for human health and safety. Energy management control system (EMCS) monitoring of garage carbon monoxide (CO) concentrations show that in a typical enclosed garage, there are three periods of concern:

- In the morning when cars enter the garage

- During the lunch break when cars leave and reenter

- At the end of the day when cars leave

This mandatory measure requires modulating ventilation airflow in large, enclosed parking garages based on pollutant concentrations. By modulating airflow based on need rather than running constant volume, the system will save energy and maintain a safe environment.

Figure 10-1: Garage CO Trends

Source: California Energy Commission

For garage exhaust systems with a total design exhaust rate ≥10,000 cubic feet per minute (cfm), §120.6(c) requires automatic controls to modulate airflow to ≤50% of design based on measurements of the contaminant concentrations. This requirement includes:

-

Minimum fan power reduction of the exhaust fan energy to ≤ 30% of design wattage at 50 percent of design flow. A two-speed or variable-speed motor can be used to meet this requirement.

-

CO concentration measured with at least one sensor per 5,000 ft2 with each sensor located where the highest concentrations of CO are expected.

-

CO concentration of 25 ppm or less as control set point at all times.

-

A minimum ventilation of 0.15 cfm/ft2 when the garage is "occupied."

-

The garage maintained at a neutral or negative pressure with respect to adjacent occupiable areas when the garage is scheduled to be occupied.

-

CO sensors certified to the minimum performance requirements listed under §120.6(c) of the Energy Codes.

-

Acceptance testing of the ventilation system per NA7.12.

Where required, the fan control must be designed to provide ≤30% of the design fan wattage at 50 percent of the fan flow. This can be achieved by either a two-speed motor or a variable-speed drive.

CO sensors (or sampling points) must be located so that each sensor serves an area no more than 5,000 ft2. Furthermore, the standard requires a minimum of two sensors per "proximity zone." Proximity zones are defined as areas that are separated by obstructions including floors or walls.

The typical design for garage exhaust is to have the exhaust pickups located on the other side of the parking areas from the source of makeup air. The ventilation air sweeps across the parking areas and toward the exhaust drops. Good practice dictates that you would locate sensors close to the exhaust registers or in dead zones where air is not between the supply and exhaust. Floors and rooms separated by walls should be treated as separate proximity zones.

- Accuracy of +/- 5%.

- 5% or less drift per year.

- Require calibration no more than once per year.

- If any sensor has not been calibrated according to the manufacturer’s recommendations within the specified calibration period, the sensor has failed.

- During unoccupied periods, the system compares the readings of all sensors. For example, if any sensor is more than 15 ppm above or below the average of all sensors for longer than four hours, the sensor has failed.

- During occupied periods, the system compares the readings of sensors in the same proximity zone. For example, if the 30-minute rolling average for any sensor in a proximity zone is more than 15 ppm above or below the 30-minute rolling average for other sensor(s) in that proximity zone, the sensor has failed.

There are no prescriptive measures for enclosed garage exhaust.

There are no separate requirements for additions and alterations.